Mechanical engineering deals with machine design, energy conversion, fuel and combustion technologies, heat transfer, materials, noise control and acoustics, manufacturing processes, rail transportation, automatic control, product safety and reliability, solar energy and technological impacts to society.

Mechanical engineering is one of the broadest and oldest branches of engineering and can require work that ranges from the design and manufacture of very fine and sensitive instruments to the design and fabrication of mammoth power plants. It deals with all aspects of the conversion of thermal energy into useful work and the machines that make this possible.

Mechanical engineering involves the creative design, manufacturing, testing, evaluation and distribution of such devices as automobiles, home appliances, spacecraft, rocket engines, air-conditioning equipment, nuclear and fossil fuel power plants, controls, robotics, and many types of instruments.

In order to prepare for such a broad field, mechanical engineers must have a solid foundation in physics, chemistry and mathematics. This field also includes studies in basic mechanics of solids and fluids, electricity and electronics, controls, dynamic analysis, mechanical design, thermodynamics, and heat transfer.

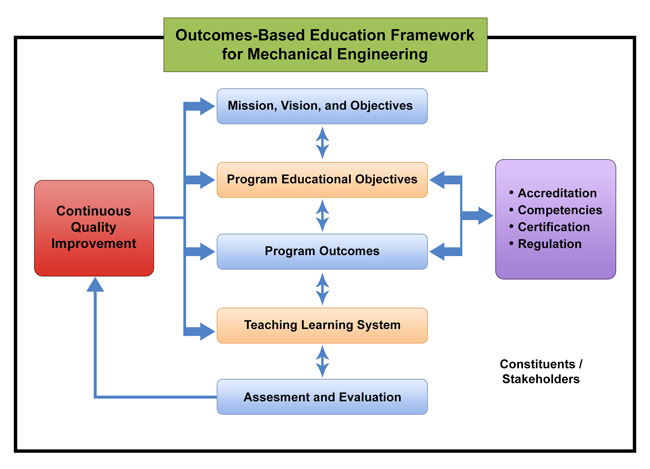

PROGRAM EDUCATIONAL OBJECTIVES

The University will produce Mechanical Engineering graduates who are:

professionally competent and globally competitive;

equipped with technical competencies and are able to contribute to the country’s social and economic progress;

lifelong learners imbued with the UE core values of Excellence, Integrity, Professionalism, Teamwork, Commitment, Transparency, Accountability and Social Responsibility.

STUDENT OUTCOMES

Ability to apply knowledge of mathematics and science to solve engineering problems.

Ability to design and conduct experiments, as well as to analyze and interpret data.

Ability to design a system, component or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability, in accordance with standards.

Ability to function in multidisciplinary teams.

Ability to identify, formulate and solve engineering problems.

Understanding of professional and ethical responsibilities.

Ability to communicate effectively.

Broad education necessary to understand the impact of engineering solutions in global, economic, environmental and societal contexts.

Recognition of the need for and an ability to engage in lifelong learning.

Knowledge of contemporary issues.

Ability to use techniques, skills and modern engineering tools necessary for engineering practice.

Knowledge and understanding of engineering and management principles as a member and leader in a team, to manage projects in multidisciplinary environments.

THE MECHANICAL ENGINEERING CURRICULUM

After completing the Fundamentals of Engineering course and learning the mathematics and science (physics, chemistry) foundation courses necessary for the study of engineering science, students proceed with the materials science, solid and fluid mechanics, thermodynamics, heat transfer, machine design, and system dynamics. Elective courses in Mechanics and Material Sciences, Design and Manufacturing, Mechatronics, and Energy Systems are pursued toward career goals. A team-based senior project completes the technical education.

The Mechanical Engineering curriculum is constructed to include abundant experiential learning. This is accomplished through the integration of laboratory experiences within the framework of the theoretical courses in the basic curriculum, and by making use of well-equipped laboratories and computing facilities. Concentrations in manufacturing engineering, control systems and automation engineering are available in this program, with a focus on robotics and automation, feedback and product and process design, and manufacturing systems. A multidisciplinary field, it integrates knowledge from the areas of science, mathematics, computers, mechanical engineering, electronics engineering, and automation. Following courses in fundamental engineering knowledge, students learn how to apply sound scientific principles to solve practical problems in industry in the area of manufacturing engineering. This concentration places an emphasis on the application of computer systems to modern manufacturing by means of topics such as robotics, computer-aided design (CAD), hydraulics and pneumatics systems (H&P), programmable logic controllers (PLC), computer-aided manufacturing (CAM) and computer-integrated manufacturing (CIM).

AREAS OF MECHANICAL ENGINEERING

CAREER OPPORTUNITIES

Mechanical engineers study the behavior of solids, liquids and gases when forces are applied to them and when they are heated and cooled. They learn how to convert energy efficiently from one form to another. Using this knowledge base, mechanical engineers play key roles in the design of transportation systems, including automobiles and space vehicles; environmental control systems and processes, including robots; energy conversion technology, including engines and power plants; biomedical devices; and so on. The tremendous breadth of Mechanical Engineering gives mechanical engineers access to employment in every major industry.

Mechanical engineers have traditionally been concerned with a great variety of technologies, such as energy conversion, machine design, instrumentation and control of physical processes, and control of the environment. Mechanical engineers fill essential roles in the entire spectrum of industrial enterprises, including even apparently “non-mechanical” ones such as the aerospace, chemical, computer and electrical power industries. Some new and exciting areas currently demanding mechanical engineers’ expertise include the artificial organ (heart, lungs, kidneys) and prosthetic limb and joint design, high-performance composite materials development, flexible manufacturing, mechanical design automation, and the control of industrial environmental pollution.

UE’S ME ACHIEVEMENTS

Philippine Accrediting Association of Schools, Colleges and Universities (PAASCU) Level II Re-Accredited

UE’s ME licensure exam topnotchers include Engrs. Richard Louie S. Macapagal (2nd, March 2010), Ian Wildon A. Dizon (10th, October 2009), Marvin V. Mayo (2nd, October 2008) and Dexter Dincog (4th, October 2007), among many others.

FACULTY

Dr. Angelita D. Guia – OIC, Mechanical Engineering

Faculty Members

UE College of Engineering-Caloocan

Angelita D. Guia

Dean

Dr. Paraluman G. Sim

Associate Dean-Engineering

Dr. Maria Amelia E. Damian

Associate Dean-Computer Studies and Systems

Engr. Edelito A. Handig

College Secretary

UE College of Engineering-Caloocan Dean’s Office

✆ Dean: (632) 8-367-4572 local 166

✆ Direct Line: (632) 8-365-4121

Associate Dean and College Secretary:

✆ 8-367-4572 local 167

✆ Direct Line: 8-365-4121

General UE CEng’g Caloocan email address:

✉ ceng.cal@ue.edu.ph

Department Chairs Office:

✆ UE Caloocan Trunkline 8-367-4572

✆ CE Department: local 171

✆ CpE Department: local 172

✆ ECE Department: local 181

✆ EE Department: local 170

✆ ME Department: local 169

✆ CS/IT Department.: local 200

Social Info